Grain products are considered the most important staple foods in the world. SchapfenMühle has the expertise and the necessary technology to process this valuable raw material into a wide variety of quality products. Find out more about the SchapfenMühle value chain and the different types of grain available.

By the time the flour is ready for use in the kitchen at home or is sitting on the supermarket shelf, the grain already has an exciting journey behind it. For centuries, farmers have brought their harvested grain to the miller. There it is ground into flour. In principle, this has not changed, but the latest technologies have always been brought in to guarantee a uniform flour quality.

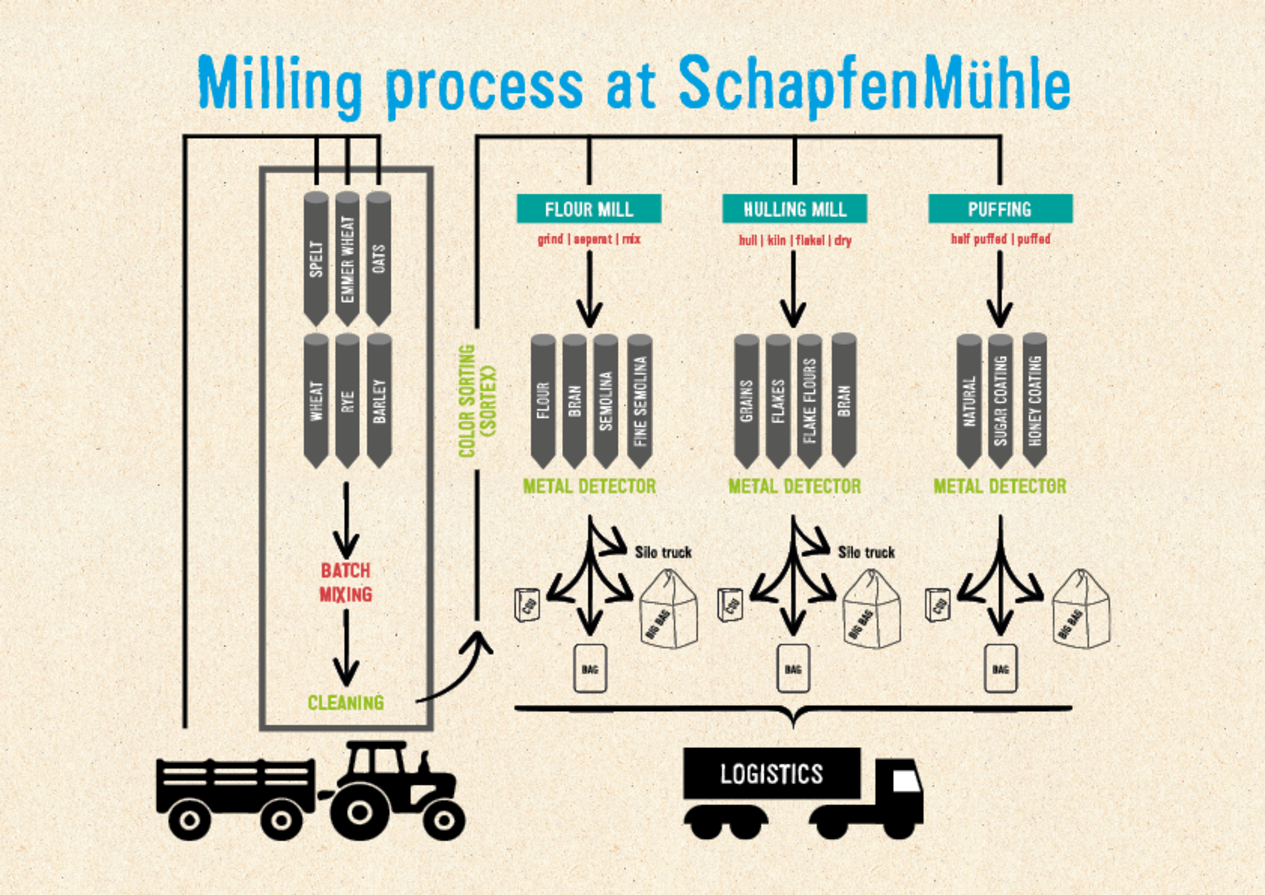

This diagram illustrates the process in place at SchapfenMühle – from the delivery of the grain, through the various processing stages, to the finished and refined grain product.

You are also welcome to download and use the chart for teaching purposes.

SchapfenMühle works together with over 600 farmers. Selected and certified seed is used for sowing. The harvested grain is delivered to and recorded directly at the SchapfenMühle premises or its external warehouse in Neenstetten. Even at this early stage, a quick analysis is conducted and the grain is stored according to its quality and type. Cultivation contracts with suppliers from the region guarantee a high level of product safety and quality for both us and our customers.

After harvesting, grain is contaminated with soil, straw and small stones. It must, therefore, be thoroughly cleaned before storage. A wide variety of equipment is used here:

Separator

This screens out everything that is larger or smaller than healthy grain.

Aspirator pre-cleaner

Sorts out lighter parts, such as straw or dust, by using airflow.

Trieur sheet

Sorts out all components that do not have a grain form, such as weed seeds.

Colour sorter

Detects unusable grains by camera technology and removes them using compressed air.

Scourer

Frees the grain from any residual dirt and dust and removes the external parts of the husk.

After these cleaning stages, the grain is prepared for milling.

Before the milling can proceed, the grain is sorted by quality and mixed together in a mixing cell. When it comes to milling, the roller mill is the most important machine in the flour mill. In it, the grain is gently crushed between two steel rollers. The grains are broken up and the endosperm is separated from the husk. The flour and husk parts are then separated with the help of sieves. This process is repeated several times until the desired flour type is achieved.

The various milled products – meal, semolina, medium-coarse grain flour and flour – are stored in flour silos according to quality. In addition, bran and germ buds are also classified among other mill products.

All finished mill products, sorted by quality, are initially stored in silos. Before filling, the cereal products are subjected to a further, careful inspection. Depending on the intended use, the products are then packaged in small packages for food retail, in sacks or in so-called "Big Bags".